There have been several times when customers approached us to ask what makes poly cartage tanks better than fibreglass or steel and what the key differences between them are. These are valid questions.

At Coerco, we sell poly products (including poly cartage tanks) for rural conditions that we are confident in. However, there is still a good chance that a fibreglass transport tank or a steel transport tank will work better for you. Why? Because farmers have their own personal preferences, and some things that might work for one’s business might not work for another.

In this article, we will explore the advantages and disadvantages of the different types of cartage tanks. We hope that by the end of this post, you will be able to make an informed decision that’ll help you make a good investment.

Here are the benefits and drawbacks of the three types of cartage tanks common in the market (poly, fibreglass and steel):

Poly Cartage Tanks: Advantages, Disadvantages & Characteristics

Advantages of Choosing Poly

Durable – the construction of poly utilises the rotational molding process, which is a high-temperature, low-pressure plastic-forming process that uses heat and biaxial rotation to produce hollow, one-piece parts.

Therefore, poly cartage tanks have no seams, bolts, joints, or weld lines that can weaken over time and jeopardize its structural integrity.

Since there are no vulnerable joints, poly is better able to resist wear and tear, eliminating the need for constant repairs.

Impact resistant – Polyethylene is a forgiving material. It absorbs shock with impact and merely bounces back to shape without breaking. This is another factor contributing to its durability.

Chemical resistant – Good quality LLDPE (linear low-density polyethylene) is impervious to chemicals. Cartage tanks made of LLDPE (like Coerco cartage tanks) can transport both water and chemicals like liquid fertiliser. LLDPE is also available in a diesel grade material.

Tensile strength – This refers to the amount of force/pressure required to break an object. Polyethylene has high tensile strength. Thus, cartage tanks made of poly don’t easily give way to the pressure of its load.

Longer lifespan with UV protection and rust resistance – Quality poly cartage tanks in Australia are constructed to withstand the country’s harsh climate. They’re built with UV-stabilised polyethylene to prevent the sun from damaging or degrading the material over time.

Additionally, polyethylene is 100% rust resistant without the need for a protective lining. The seamless design means there are no fittings or bolts involved that make poly susceptible to rust/corrosion.

These above traits make poly cartage tanks last long: over 20 years.

Lightweight – Poly cartage tanks are easier to position and transport. Because they are all around easy to maneuver, they’re ideal for farm setups that have to remove their cartage tanks from trucks for other uses around the property.

Shorter lead times which contributes to affordability – With roto-moulding (rotational moulding), raw materials are relatively less expensive. The moulds used to produce the transport tanks are also affordable to make, making the construction of multiple moulds possible, and producing multiple cartage tanks achievable, fast, and easy. This translates to shorter production times and lower production costs compared to other tanks.

Environmental-friendly – Polyethylene is 100% recyclable. Coerco has an established recycling program that turns waste poly material into other poly products.

Food-grade – Poly cartage tanks are food-grade without needing a lining. This is an advantage because once a tank’s lining is damaged, it ceases to be safe for transporting drinking water. Since poly doesn’t need a coating to be food-grade, it’s considered food-grade for life.

Low-maintenance – Poly transport tanks, being seamless and flexible, and thus, less prone to damage, don’t require a lot of repairs. Plus, they are easy to clean. You can give a poly cartage tank a good wash without running the risk of damaging the inner lining (because poly doesn’t need one).

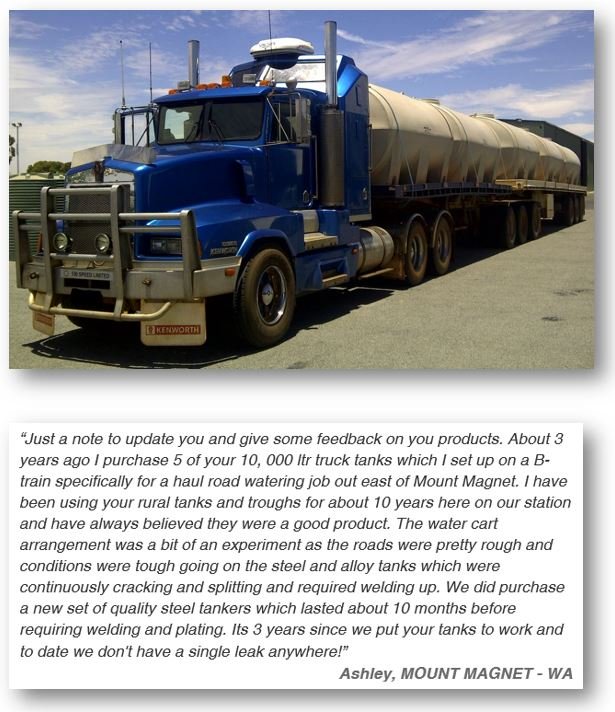

See this poly cartage tank testimonial:

Disadvantages of Choosing Poly

High fire risk – Poly could get easily damaged during a fire just like any vehicle it is mounted on or towed behind.

Needs a professional poly welder when damaged – Although it is highly unlikely for well-designed cartage tanks to break or get cracked, they need a professional poly welder to repair them when they do.

Built in baffles aren’t available for all sizes – Poly cartage tanks 10,000-litres and above are not manufactured with built-in baffles as they are too big for a built-in baffle to be effective against liquid surge. In this case, baffle balls are a great alternative to keep liquid loads stable during transport.

On the flip side, tanks without built-in baffles could be an advantage for some people. This is because built-in baffles could accumulate dirt in some places (e.g. in the corners), making large cartage tanks harder to clean. Note that dirt could contaminate your next load.

May need more baffle balls – Larger cartage tanks (10,000 litres and above) need more baffle balls since they don’t have built-in baffles. This could add to your initial cost as baffle balls are priced separately.

Whereas baffle balls don’t need to be cleaned if your cartage tank is transporting the same liquid each time, they do need to be cleaned if you need to cart a different liquid than the one before it in order to avoid contamination.

As an aside, baffle balls are more effective at minimizing liquid surge in different directions than traditional built-in baffles. Traditional built-in baffles are made to minimise liquid surge end to end, but not side to side.

NOTE: You won’t need any baffle balls when you’re transporting liquids in full loads. Liquid surge is less of an issue if your tank is full.

Fibreglass Cartage Tanks: Advantages, Disadvantages & Characteristics

Advantages of Choosing Fibreglass

Rust resistant – Fibreglass material, like polyethylene, is resistant to rust.

Lightweight – Compared to steel cartage tanks, fibreglass tanks are more lightweight than steel.

Tensile strength – Fibreglass cartage tanks have adequate tensile strength to resist damage due to liquid pressure.

Chemical resistant – Fibreglass cartage tanks are impervious to chemicals and can safely carry liquid fertilisers.

Fully baffled – Fibreglass transport tanks may be fully baffled with built-in baffles, even in larger sizes.

Disadvantages of Choosing Fibreglass

Rigid - Fibreglass is an inflexible material. It can easily crack and break in high-impact scenarios (e.g. rough terrain), making it less than satisfactory for transporting across bumpy farmlands, hills, or other uneven surfaces.

Damage to fibreglass can start with small unnoticeable cracks (even microscopic ones) that only get bigger with time.

Requires a gelcoat – Fibreglass transport tanks require an external gelcoat to make them UV-resistant and to keep temperatures to a minimum. However, if damaged, heat penetration becomes easier.

Requires an internal lining – Fibreglass transport tanks need an internal food-grade coating to be considered food-grade. Otherwise, it won’t be safe for transporting potable water. Care must be done to prevent damage to this lining.

Not 100% rust-free – Even though fibreglass material is rust-free, fibreglass cartage tanks, per se, aren’t. Fibreglass tanks are made of different parts joined together. Thus, certain parts like screws on joints may be susceptible to localised corrosion.

Labour intensive – In contrast to poly, which is manufactured through an automated roto-moulding process, fibreglass cartage tanks are handcrafted to be complete, and thus, could be vulnerable to human error.

Steel cartage tanks: Advantages, Disadvantages & Characteristics

Advantages of Choosing Steel

Available in larger sizes – This makes steel transport tanks more suitable for transporting huge loads of liquids in one tank.

Strong – Steel is made of hardy material and physically stable.

Fire resistance – Steel cartage tanks are non-combustible, making them less likely to catch fire.

Readily repaired when damaged – When a steel transport tank gets damaged, you have the option to repair it yourself or by a metal work fabricator.

Disadvantages of Choosing Steel

Strong but not durable – There’s a difference between strong and durable. Although steel tanks are strong, their construction, which is either welded or bolted together, can be the cause of a weakened structural integrity over time. This makes them less able to withstand wear and tear (less durable), making repairs necessary.

Prone to rust – Galvanised steel cartage tanks require a protective coat of zinc or paint or similar to protect it from corrosion. Damage to this coating predisposes a steel transport tank to rust. If coated internally with a zinc coating, it may leach into potable water and impart an unpleasant metallic taste.

Since steel transport tanks aren’t built as one-piece products, screws, joints, and rivets may not be completely rust resistant, and parts of the tank where rust takes place may be weakened.

Labour intensive – Relative to poly cartage tanks, steel tanks require many parts to be welded together, making them more labour-intensive to produce in comparison to poly cartage tanks.

Heavier – Free standing steel tanks aren’t as easy to maneuver as poly or fibreglass. Therefore, they’re not easy to position for other uses around the property. Or bigger machines may be required to move them around.

What to Consider Before You Choose Poly, Fibreglass or Steel Liquid Transport Tanks

Your Budget

Although it’s understandable to want the cheapest option, don’t forget to consider the cost you will incur on repairs with higher maintenance / lower quality cartage tanks.

Lifecycle

How long would you want to keep your cartage tank? Would you rather replace tanks every few years or do you prefer a cartage tank that would last longer, eliminating the need for replacements?

Your Environment

There are situations where one transport tank may be more advantageous than another. Figure out potential problem areas that might affect the longevity of your cartage tank and pick one that would have greater resistance to the identified problem areas.

Conclusion

All transport tanks stated above are great options. It’s all just a matter of preference and your individual requirements.

You may ask yourself these guide questions to help you decide:

- How much money am I comfortable spending on a liquid cartage tank?

- How important to me is using recycled or recyclable materials?

- How often will I find myself in challenging routes?

- How much money and time am I willing to spend on repairs?

- What size of cartage tank do I need?

Related topics:

Product Spotlight: Water Cartage Tanks

5 Reminders Around Safety When Securing Cartage Tanks for Transport

Coerco has been successfully supplying cartage tanks suitable for water transport and liquid fertiliser transport across Australia for decades.

Being a rural-based manufacturer of poly cartage products, Coerco cares about the needs of agriculture and makes sure to manufacture transport tanks that directly address the challenges in liquid cartage.

What do you think about this post?

Comments